Grinding and Polishing Method of Titanium and Titanium Alloy Parts

Key words: TC4 titanium alloy parts, titanium alloy grinding, titanium polishing, mechanical grinding, ultrasonic grinding, electrolytic mechanical composite grinding, chemical polishing, electrolytic polishing

1. Mechanical grinding:

Titanium has high chemical reactivity, low thermal conductivity, high viscosity, low mechanical grinding ratio and is easy to react with abrasive tools. Ordinary abrasives are not suitable for the grinding and polishing of titanium. It is preferable to use a super-hard abrasive having good thermal conductivity such as diamond or cubic boron nitride. The polishing line speed is generally 900~1800m/min. Otherwise, the titanium surface is prone to burns and microcracks.

2.Titanium alloy ultrasonic grinding:

Through the ultrasonic vibration, the abrasive grains between the grinding head and the surface to be polished are moved relative to the surface to be polished to achieve the purpose of grinding and polishing. Its advantage is that the grooves, pits and narrow parts which can not be grinded by conventional rotary tools become easier, but the grinding effect of larger castings is not satisfactory.

3. Electrolytic mechanical composite grinding of titanium parts:

With conductive abrasive tools, electrolyte and voltage are applied between the abrasive tool and the abrasive surface. Under the combined action of mechanical and electrochemical polishing, the surface roughness is reduced and the surface gloss is improved. The electrolyte is 0.9NaCl, the voltage is 5v, and the rotation speed is 3000rpm/min. This method can only grind the plane, and the grinding of the complex denture bracket is still in the research stage.

4. Barrel-grinding titanium dentures:

By using the centrifugal force produced by the rotation and rotation of the grinding barrel, the relative friction motion between the denture and the abrasive in the barrel can reduce the surface roughness. Grinding automation, high efficiency, but can only reduce the surface roughness and can not improve the surface gloss, the grinding accuracy is poor, can be used with the deburring and rough grinding before the titanium denture polishing.

5. Chemical polishing of titanium:

Chemical polishing is to achieve the purpose of leveling and polishing by the oxidation-reduction reaction of metals in chemical medium. Its advantage is that chemical polishing has nothing to do with metal hardness, polishing area has nothing to do with structure and shape, and all parts contacted with polishing fluid are polished. It does not require special complicated equipment and is easy to operate. It is suitable for the polishing of complex structure titanium denture brackets. However, the process parameters of chemical polishing are difficult to control, and it is required to have a good polishing effect on the denture without affecting the accuracy of the denture. The better titanium chemical polishing solution is HF and HNO 3 in a certain proportion. HF is a reductant, which can dissolve titanium metal and play a leveling role. At a concentration of <10%, HNO3 acts as an oxidation agent to prevent excessive dissolution and hydrogen absorption of titanium, and at the same time, it can produce a brightening effect. Titanium polishing solution requires high concentration, low temperature and short polishing time (1~ 2 minutes).

6. Electrolytic polishing of titanium alloy parts:

Also known as electrochemical polishing or anodic dissolution polishing. Due to the low conductivity of titanium, the oxidation performance is extremely strong. It is almost impossible to polish titanium by using an acidic acid electrolyte such as HF-H3PO4 or HF-H2SO electrolyte. After the external voltage is applied, the titanium anode is immediately oxidized, and the dissolution of the anode cannot be performed. However, the use of anhydrous chloride electrolyte at low voltage has a good polishing effect on titanium. Small titanium specimens can be mirror polished, but for complex restorations, full polishing is not possible. Perhaps the problem of changing the shape of the cathode and the additional cathode can solve this problem, and further research is needed.

1. Mechanical grinding:

Titanium has high chemical reactivity, low thermal conductivity, high viscosity, low mechanical grinding ratio and is easy to react with abrasive tools. Ordinary abrasives are not suitable for the grinding and polishing of titanium. It is preferable to use a super-hard abrasive having good thermal conductivity such as diamond or cubic boron nitride. The polishing line speed is generally 900~1800m/min. Otherwise, the titanium surface is prone to burns and microcracks.

2.Titanium alloy ultrasonic grinding:

Through the ultrasonic vibration, the abrasive grains between the grinding head and the surface to be polished are moved relative to the surface to be polished to achieve the purpose of grinding and polishing. Its advantage is that the grooves, pits and narrow parts which can not be grinded by conventional rotary tools become easier, but the grinding effect of larger castings is not satisfactory.

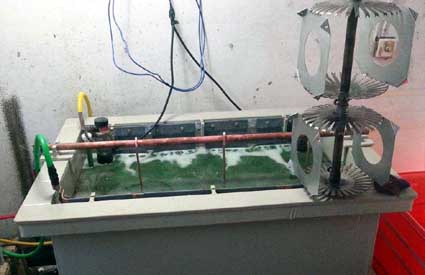

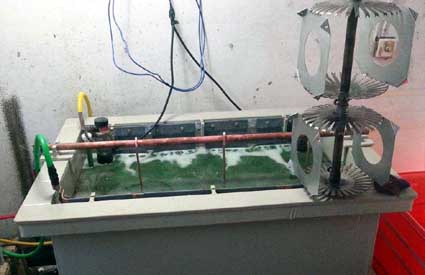

3. Electrolytic mechanical composite grinding of titanium parts:

With conductive abrasive tools, electrolyte and voltage are applied between the abrasive tool and the abrasive surface. Under the combined action of mechanical and electrochemical polishing, the surface roughness is reduced and the surface gloss is improved. The electrolyte is 0.9NaCl, the voltage is 5v, and the rotation speed is 3000rpm/min. This method can only grind the plane, and the grinding of the complex denture bracket is still in the research stage.

4. Barrel-grinding titanium dentures:

By using the centrifugal force produced by the rotation and rotation of the grinding barrel, the relative friction motion between the denture and the abrasive in the barrel can reduce the surface roughness. Grinding automation, high efficiency, but can only reduce the surface roughness and can not improve the surface gloss, the grinding accuracy is poor, can be used with the deburring and rough grinding before the titanium denture polishing.

5. Chemical polishing of titanium:

Chemical polishing is to achieve the purpose of leveling and polishing by the oxidation-reduction reaction of metals in chemical medium. Its advantage is that chemical polishing has nothing to do with metal hardness, polishing area has nothing to do with structure and shape, and all parts contacted with polishing fluid are polished. It does not require special complicated equipment and is easy to operate. It is suitable for the polishing of complex structure titanium denture brackets. However, the process parameters of chemical polishing are difficult to control, and it is required to have a good polishing effect on the denture without affecting the accuracy of the denture. The better titanium chemical polishing solution is HF and HNO 3 in a certain proportion. HF is a reductant, which can dissolve titanium metal and play a leveling role. At a concentration of <10%, HNO3 acts as an oxidation agent to prevent excessive dissolution and hydrogen absorption of titanium, and at the same time, it can produce a brightening effect. Titanium polishing solution requires high concentration, low temperature and short polishing time (1~ 2 minutes).

6. Electrolytic polishing of titanium alloy parts:

Also known as electrochemical polishing or anodic dissolution polishing. Due to the low conductivity of titanium, the oxidation performance is extremely strong. It is almost impossible to polish titanium by using an acidic acid electrolyte such as HF-H3PO4 or HF-H2SO electrolyte. After the external voltage is applied, the titanium anode is immediately oxidized, and the dissolution of the anode cannot be performed. However, the use of anhydrous chloride electrolyte at low voltage has a good polishing effect on titanium. Small titanium specimens can be mirror polished, but for complex restorations, full polishing is not possible. Perhaps the problem of changing the shape of the cathode and the additional cathode can solve this problem, and further research is needed.